No matter what type of Autonomous Mobile Robots (AMR) project you have in mind for your facility, you will need five key points of data to start the process. So, before you engage an professional integrator such as ELT Systems Group, here are the things you will want to consider.

#1 Pick and Drop Pairs

This may be obvious, but it requires some thought! Before any project can get off the ground you need to determine where an AMR will pick up and drop off product. Will you utilize a single pick point or use multiple drop points? Adding multiple pick and drop combinations makes the system more complex and will increase the overall fleet size. So, first determine the most important pick and drop locations and expand your project from there.

#2 Throughput

Once all pick and drop pairs have been determined, determine the potential throughput of that route. At the beginning of the project having a precise figure is not necessary, but understanding this calculation, along with other data points will be used to determine fleet size. Obviously, there is a huge difference between making trips from a staging area to the docks 5 times an hour vs 20 times an hour. Systems with higher throughput needs maybe impacted by traffic, and that must also be considered.

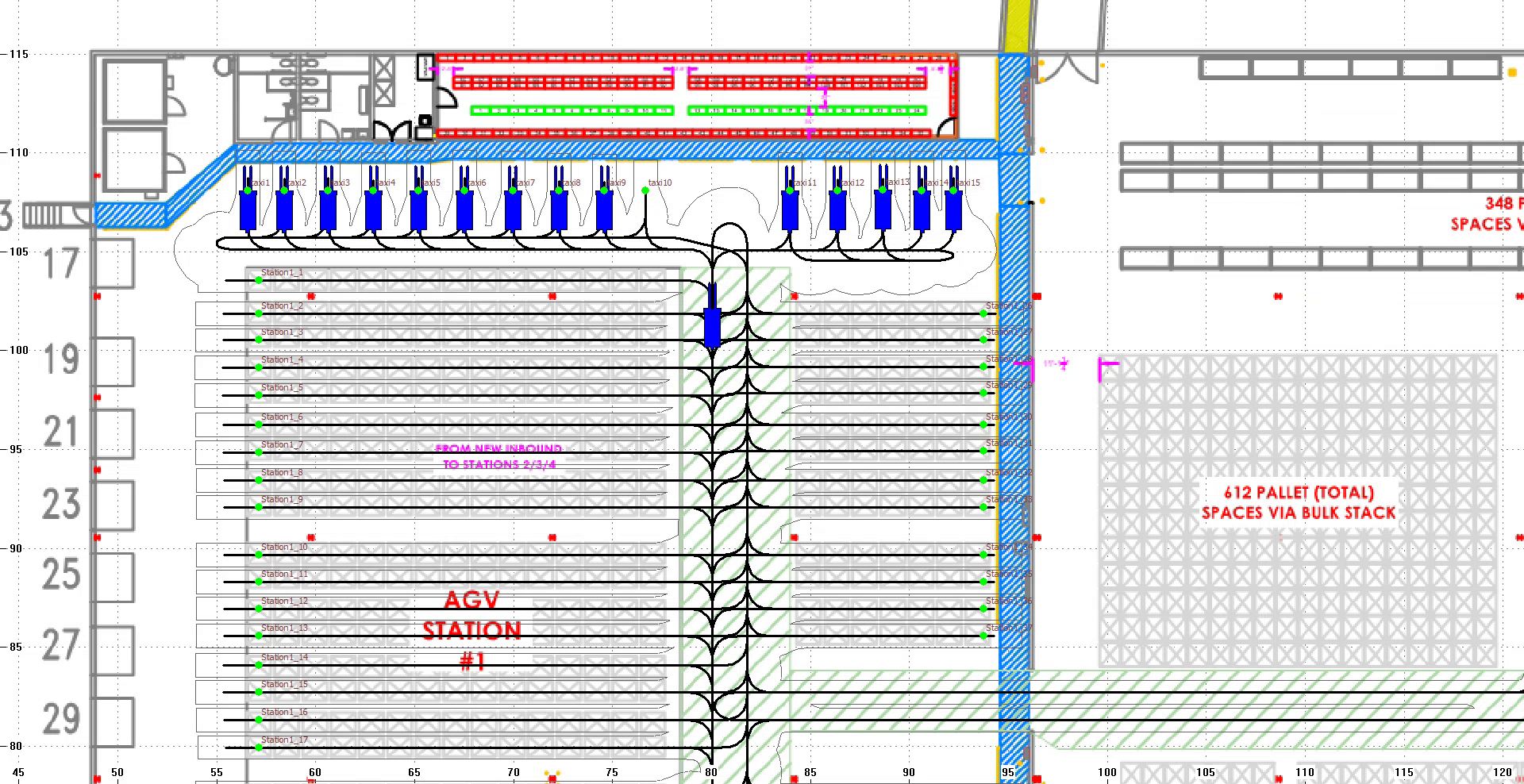

#3 Distance Travelled

Know your distances and be prepared with a CAD drawing of your facility! Data Points #1 through #3 will make up nearly most of the first round of projections on project cost and fleet size. Distance travelled is important because it obviously impacts the time needed to transport materials. The longer the distances the more AMRs will be needed to match throughput metrics. If a CAD file is not available at the onset, then an estimated distance from pick to drop is good enough to kick off budgetary considerations.

#4 Mission Triggers

It may seem like a small matter, but how AMRs will be controlled is very important and will impact the scope of the project. Will your system Robot Manager work independently of a WMS? If so, how will it receive input on your pick and drop locations? Will there be a control panel at the pick location, such as a pack station that signals the pickup of a tote? Will there be a photo eye on your conveyor? How will the system identify the drop location if a pick location has multiple drop locations? While not all of these questions need answered on Day 1, they will quickly become part of the discussion.

#5 Operational Hours

How long the AMRs need to work each day ultimately determines some vital elements of the project, not the least of which is your Return on Investment (ROI). The less time AMRs are actually working, the longer your ROI. So, part of the project consideration is making sure the AMRs have missions available throughout your facility’s operational hours. Operational hours are also used to determine energy solutions, including the number of batteries, chargers, and “charging missions” required by each AMR. In turn, those figures, impact fleet size.

We require each one of these five data points in order to provide a rough order of magnitude proposal. If you are considering an AMR/automated solution for your material handling needs, we encourage you to begin thinking about these key elements. You will be way ahead of the game when the first phase of the project begins. If you have any questions or are interested in starting an AMR project, contact ELT Systems Group and we will be more than happy to assist gather data to answer all the questions above.

Contact ELT Systems Group for a free consultative conversation and we’ll begin working on the right solutions to the challenges you are facing in today’s every changing world.

Contact the systems group or Jason Dodge directly for further information and to get started on your project today.

Jason Dodge Automation Manager | Systems Division Eastern Lift Truck Co., Inc. Cell: (609) 605-1043 Email: jdodge@easternlifttruck.com