Quick disconnect couplings, also known as “QDCs or QDs” have many uses. In the materials handling world, these detachable hydraulic connections provide a safe and fast way to release and reconnect hydraulic hose connections without the need for special tools.

QDs are found in warehouses and manufacturer plants where forklift operators are asked to use one forklift to handle multiple tasks that involve the change out of a front-end hydraulic attachment. For example, an operator may use a standard load fork set-up the majority of the time, but weekly shipments of non-palletized materials arrive on a slip sheet and need to be unloaded. Using quick disconnects, the operator could easily install a slip sheet attachment on the forklift, move the load and then convert back to the standard load fork setup. Another example may involve using quick disconnects to install a clamp attachment to handle occasional drum shipments.

An attachment mounted to a forklift without quick disconnects, is considered a dedicated attachment, meaning, its removal from the forklift requires a technician and significant labor. Conversely, an attachment mounted with a set of quick disconnects is considered non-dedicated and may be removed and reinstalled without a technician or labor expense.

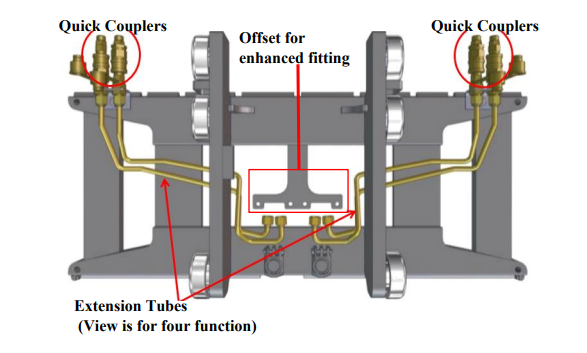

A quick disconnect set up, running from a forklift to an attachment, involves a junction box, male and female hydraulic couplers, related O-rings, fittings, and a valve body. When they are working properly, QDs maintain the oil pressure in the hydraulic lines and have little to no oil spillage.

Quick disconnects can improve productivity and reduce the need for multiple forklifts.

If you have any questions about how to safely interchange attachments, please contact a member of our Service Department. We are always happy to assist.