Benefits of Material Handling Equipment Solutions

Warehouses and distribution centers are busy work environments that require a steadfast focus on efficient layout and workflow to optimize productivity and remain competitive in their market. Thankfully, forward-thinking facility operators have a variety of material handling equipment and design solutions at their disposal to improve dock-to-stock cycle times and order-picking capacity, reduce product damage,…

Trash Removal

Robotic lift trucks have the best return on investment when they are continuously working. A robot can be used in many ways, but instead of sitting idle it should have other low priority tasks to complete. One of these tasks can be bringing trash from multiple locations in a facility to a compactor or drop…

Work In Progress Goods

One task in a manufacturing process is moving work in progress goods from one working cell to another. This is typically done by conveyor systems, manually driven tuggers with a train of carts or manual pallet jacks. All these solutions require labor or expensive transport systems. Robotic lift trucks can provide multiple solutions to these…

Empty Pallet Removal

Within a manufacturing cell, pallets containing materials come in, and empty pallets need to be returned. These pallets can contain anything from packaging material, work in progress goods, or raw materials. Once the product is used up, and more is required, empty pallets need to be removed, or stored for future disposal. Robotic lift trucks…

End of Aisle to Outbound Staging

Inside a warehouse, material needs to be removed from racking and be brought to some form of outbound staging areas. This is done with reach trucks not only taking pallets from height but then doing long distance horizontal transport or reach trucks placing product in a local staging area where another manual operator does the…

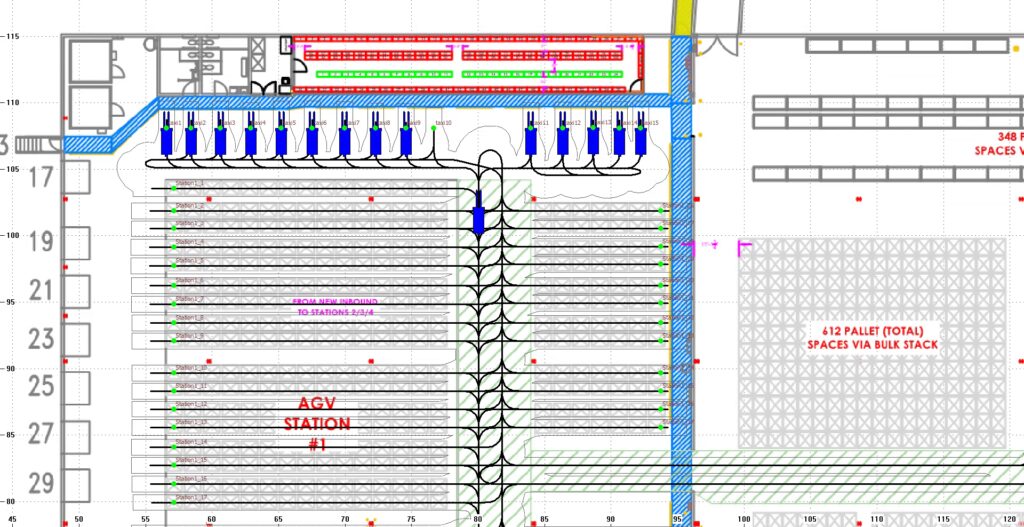

Inbound Receiving to End of Aisle

Whether you’re in a manufacturers warehouse or a distribution center, pallets need to be moved from inbound to racking. Many instances have manual operators moving single or multiple pallets at a time with a pallet jack and bringing them to aisles for vertical lift trucks to put them into racks. Robotic lift trucks can be…

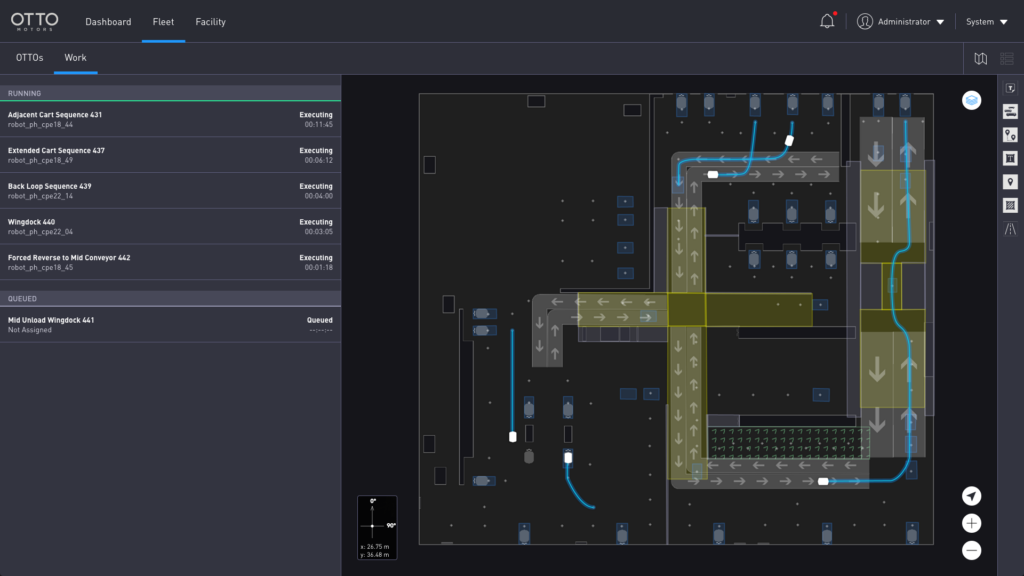

What is the difference between an AGV and an AMR?

If you’ve been investigating robotic material handling equipment you inevitably have come across the terms AMR and AGV. So what is the difference? Although some may unknowingly use the terms interchangeably, there is a significant difference between the two types of vehicles. An AGV is a robotic vehicle that must follow a discrete path, from…

Three Considerations for Gaining Efficiency in AMR Deployments

If you are investigating automating pallet moves in your facility, there are three main things you need to consider.

Top 3 Applications for AMRs

There are many operations that can benefit from utilizing Autonomous Mobile Robots (or AMRs).

How Automation Pays for Itself

In today’s marketplace, robotics and automation are gaining traction in places that never considered them before.

Top Five Data Points for Designing an AMR Project

No matter what type of Autonomous Mobile Robots (AMR) project you have in mind for your facility, you will need five key points of data to start the process.

Automation Solves Labor and Real Estate Challenges

There are many challenges in today’s manufacturing and material handling world and the two biggest ones are labor and real estate.

- « Previous

- 1

- 2

- 3

- Next »