Emergency Procedures

Every facility has its own safety procedures in the case of an emergency. In the case of a fire, for example, all fork truck operators must park their trucks in a place that does not obstruct any emergency exits, fire extinguishers etc. When it comes to robotic lift trucks, the requirements are the same for…

Inbound to Quality Control or Staging

In some operations like cross-docking or manufacturing, pallets that are delivered to an inbound staging area need to moved throughout the facility to different quality control or staging areas. The pallets are placed in staging lanes and need to be scanned and delivered to an appropriate area. In order to automate these workflows a myriad…

Inter-Building Transport

Large warehouses and distribution centers have the challenge of moving pallets from one side of a build to another. This could be movement from inbound, long- or short-term storage, to an outbound or quality control area. Regardless of where the pallets are moving to and from, manual operators are required to travel long distances moving…

Automating Milk Runs in Production

A typical application for manual operators is to drive tuggers pulling carts, with materials to be delivered to multiple locations, in a production facility, aka a milk run. A robotic lift truck solution automates tugger routes by removing the need for manual operators to drive in loops all day. The robotic solution has a capacity…

A Guide to Warehouse Automation

Warehouse automation has transformed the nature of the industry, bringing robotics, equipment and software to nearly every task in the facility. As automation technology becomes more attainable and affordable, warehouse organizations must have a pulse on it. Adopting automation techniques will be crucial to staying competitive and getting ahead of the curve. As a trusted…

End of Production

The final production of goods need to be moved after completion to different locations like storage, pallet wrappers, palletizers, outbound staging areas, quality control or packaging. All these processes can be done with a robotic lift trucks. Robotic lift trucks can integrate with conveyor systems or palletizers so that they can called for pickup. Once…

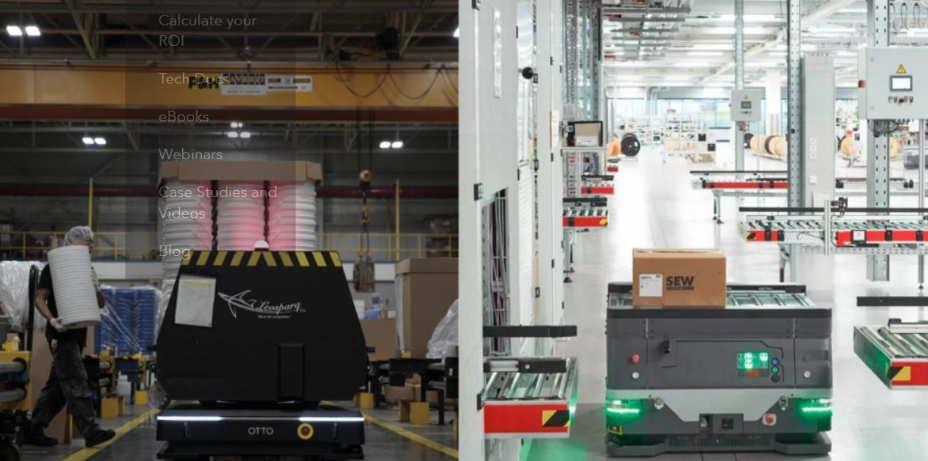

The Future of AMRs and AGVs in Material Handling

In December 2022, OTTO Motors hosted “The Best of Both Worlds: Unlocking the Productivity of AGVs and AMRs”: a webinar that analyzed the differences between AMRs and AGVs, from their technology to their applications. This webinar introduced the idea of Graph-based Planning, an algorithm that enables manufacturing facilities to achieve the benefits of both AMRs and AGVs…

Budget Considerations When Selecting an AMR Solution

Autonomous material movement technologies, specifically autonomous mobile robots (AMRs), have gained popularity as the answer to labor shortages, supply chain disruption and employee safety concerns in manufacturing facilities around the world. As you research options, you will want to understand what technologies are available, how they differ, and the related costs, to implement them. Every…

Trash Removal

Robotic lift trucks have the best return on investment when they are continuously working. A robot can be used in many ways, but instead of sitting idle it should have other low priority tasks to complete. One of these tasks can be bringing trash from multiple locations in a facility to a compactor or drop…

Dock Leveler and Truck Restraint System Support and Sales

Having high-quality, dependable dock equipment is important for a variety of reasons, not the least of which is safety. Eastern Lift Truck Co.’s Dock & Door Division sells all different types of dock equipment, including a variety of dock levelers and restraint systems, and provides the routine maintenance and emergency repair service needed to keep…

Benefits of Material Handling Equipment Solutions

Warehouses and distribution centers are busy work environments that require a steadfast focus on efficient layout and workflow to optimize productivity and remain competitive in their market. Thankfully, forward-thinking facility operators have a variety of material handling equipment and design solutions at their disposal to improve dock-to-stock cycle times and order-picking capacity, reduce product damage,…

Trash Removal

Robotic lift trucks have the best return on investment when they are continuously working. A robot can be used in many ways, but instead of sitting idle it should have other low priority tasks to complete. One of these tasks can be bringing trash from multiple locations in a facility to a compactor or drop…