“Though the danger on the rocks is surely past, still I remain tied to the mast.” -Lyrics to Home at Last by Steely Dan

What’s the first thing you think of when you read the word mast? Most people think of a sailboat. In nautical terms, the mast is a vertical spar, made of wood or metal, that supports a ship’s yards and boom, all of which, in turn, hold the ship’s sails. A sailboat without a mast is dead in the water.

In the materials handling world, a mast is also critical. A forklift mast is the vertical structure that supports components that hydraulically lift, lower, and position loads. Mast specifications vary depending on the overall lifting, stacking, tilting, and capacity requirements. Let’s look at the four major types of forklift masts.

Forklift Mast Types

Simplex Mast, aka Standard Upright

The Simplex mast, also called a standard mast or upright, is a two-rail assembly. It has a stationary rail and an inner, movable rail. Of the four mast types, it offers the least amount of lift and no free lift.

Duplex Mast, aka Two-Stage Mast or Upright

The Duplex mast is a two-rail assembly that looks and operates just like the Simplex mast. However, the addition of a center-mounted hydraulic cylinder, called a free lift cylinder, allows the mast’s carriage and forks to raise a specific height, before the “nested” inner rail begins to raise. The resulting “free lift” allows the forklift operator to lift and stack loads in areas with limited overhead clearance. Forklifts with duplex masts may have limited or full free lift. Operators must always be mindful of overhead obstacles and account for the height of their load backrest extension if it’s taller than the load.

Triplex Mast, aka Triple Mast or Three-stage Upright

The Triplex mast is the most popular and versatile mast. It provides full free lift and incorporates a three-rail assembly, one stationary rail and two inner, movable rails, which extends overall lift heights.

Quad Mast, aka Quadplex Mast

As its name implies, the Quad mast is a four-rail assembly. It has one stationary rail and three inner, movable rails and provides the highest possible lift heights of the four mast types.

Mast Nomenclature

Those familiar with Yale forklifts may know their model number (nomenclature) provides mast type. These four letters indicate mast type on a Yale forklift:

V = Simplex mast

F = Duplex mast

E = Triplex mast

Q = Quad mast

Example: The “E082” at the end of Yale Model number ERC030VAN36TE082, indicates the forklift was manufactured with a Triplex mast that is 82” tall when collapsed (forks fully lowered).

Additional forklift mast designations and acronyms include:

LFL = Limited Free Lift

FFL = Full Free Lift

TSU = Three Section Upright

MFH = Maximum Fork Height

MFL = Maximum Fork Lift (same as MFH)

OLH = Overall Lowered Height

Hi-Vis = High Visibility Mast*

These masts are designed for maximum visibility with widely spaced channels, lift chains and main lift cylinders.

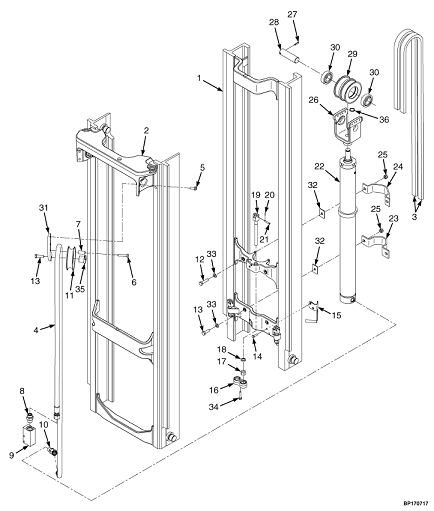

A mast is more than rails. How many mast components are you able to name in this photo of the two moving sections of a Triplex mast?

Chain Anchor (19)

Free Lift Cylinder (22)

Chain, aka Load Chain (3)

Chain Sheave (29)

Inner Mast (1)

Intermediary Mast (2)

Hose Sheave (11)

Hose Assembly (4)

Grease Fittings (8 and 10)

Most forklift masts are extremely durable. But routine inspection and maintenance is important to keep them functioning properly. Chain links should be checked for stretching, rollers adjusted, dirt and debris removed, channels and fittings greased, and metal examined for fatigue or cracks, etc. The mast forward and rear tilt should also be checked and kept within the manufacturer’s guidelines.

If you have any questions about forklift masts or interest in setting up a maintenance program for your forklift, please contact us. We’re always happy to help.