If you’ve been investigating robotic material handling equipment you inevitably have come across the terms AMR and AGV. So what is the difference?

- AGV – Automated Guided Vehicle

- AMR – Autonomous Mobile Robot

Although some may unknowingly use the terms interchangeably, there is a significant difference between the two types of vehicles.

An AGV is a robotic vehicle that must follow a discrete path, from which it can never deviate. This path may follow a physical installation like tape, magnets or wire guidance or it may be more high-tech like a digital path designed in its robotic software.

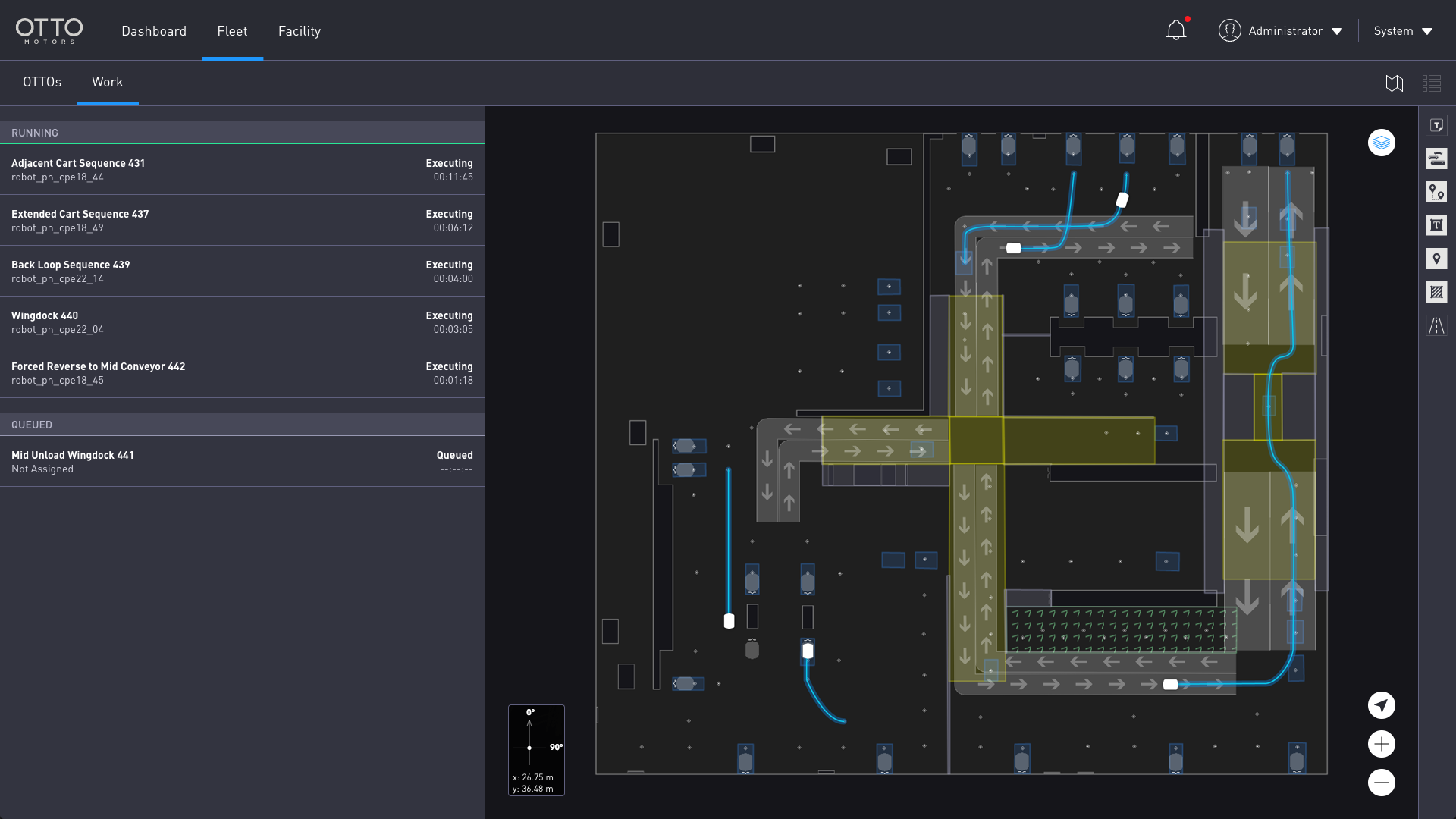

An AMR is a robotic vehicle that operates in a designed space where the software dictates the most optimal path from point A to B with the primary concern for safety. Simply put, an AGV must be guided, and an AMR is only guided by safety and an area of space.

The main benefit of an AMR is that it will have the ability to avoid obstacles and maintain its path. This vastly decreases stoppages and increases overall efficiency and throughput. An AGV will detect obstacles but will come to a complete stop until they are removed.

AMR software has design capabilities of creating traffic rules in your facility, such as stopping at intersections, use of one-way traffic lanes, or adherence to slow down areas, etc. AMRs represent highly flexible technology and may be safely and easily integrated into nearly any facility.

If you’re interested in automating your material handling application, make sure you reach out to ELT Systems Group and see how we can help.

Contact ELT Systems Group or Jason Dodge directly for further information and to get started on your project today.

Jason Dodge Automation Manager | Systems Division Eastern Lift Truck Co., Inc. Cell: (609) 605-1043 Email: jdodge@easternlifttruck.com